Utilize the generator monitoring system to reduce your operating costs

Will an unexpected power interruption have an impact on your overall productivity? Is it necessary for you to monitor generators located at numerous locations?

If "Yes" then Aqualink's AI-based Smart Diesel Generator Monitoring is the answer you've been waiting for to ensure your company's sustainability. In order to assist you to manage the effectiveness of your business and provide you peace of mind, we monitor the crucial KPIs that you demand from your remote generators.

- Enhanced asset tracking

- Increased equipment reliability

- Centralized surveillance

- Fuel tracking and theft prevention

Key benefits of genset monitoring system

Monitoring in real-time

Monitoring in real-time

Real-time monitoring of each generator's important metrics is required, and SMS/Email warnings are available for quick response.

Surveillance and security

Surveillance and security

Watch the points of entry and departure as well as the movement of persons inside the building constantly, and get notifications if unlawful access is made.

Scheduling Automation

Scheduling Automation

Eliminating manual handling will boost user convenience as you may remotely turn on and off your Generators from anywhere.

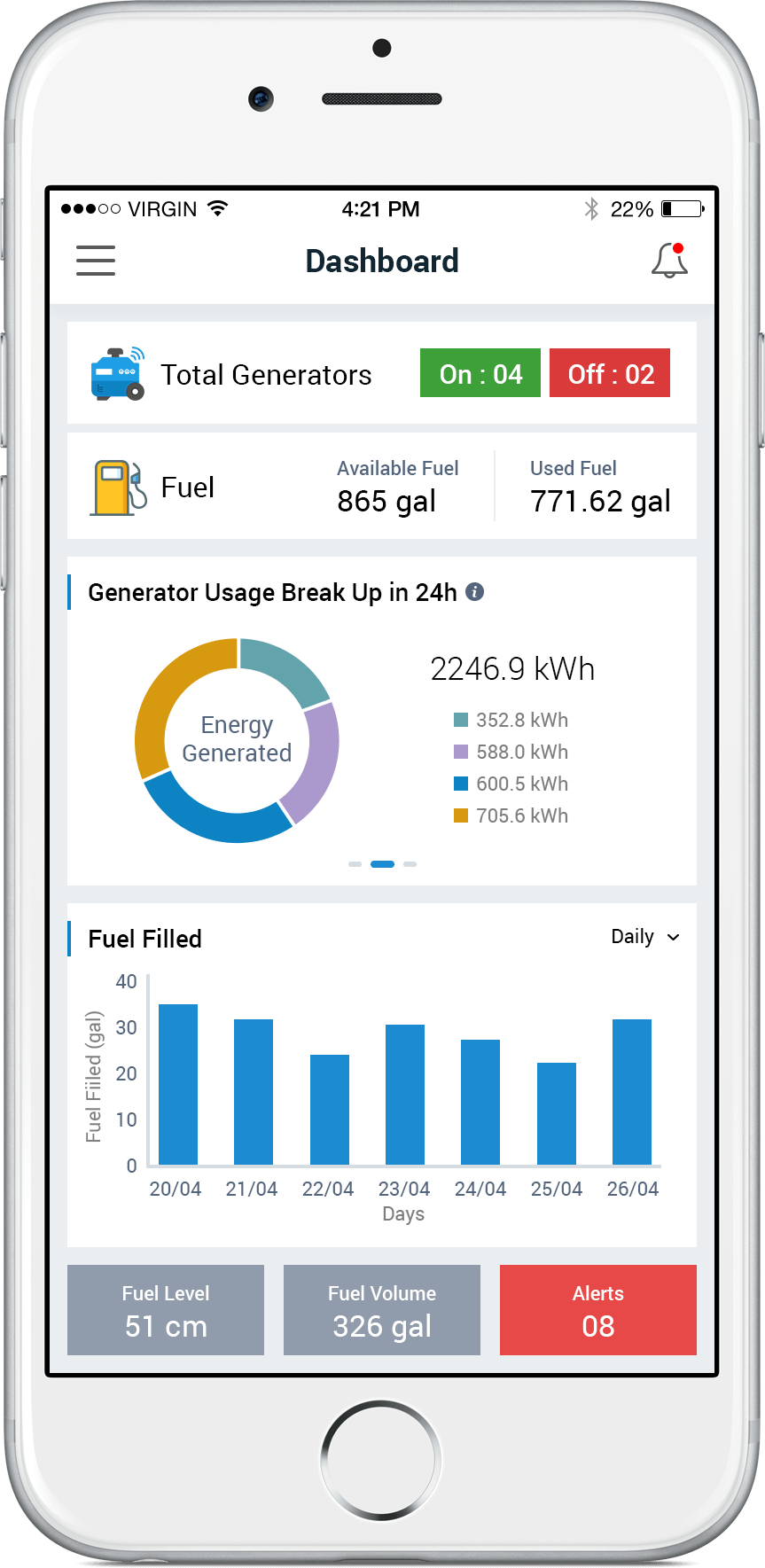

Dashboard for Reporting

Dashboard for Reporting

Easily spot a discrepancy between the amount of fuel spent and the amount of energy generated by receiving daily, weekly, or monthly information on fuel consumption rates.

Features

-

Monitoring of fuel/leaks in real time

-

Sends notifications if there is a variance

-

Identifies possible mechanical issues

-

Root cause investigation

-

Warnings for fuel theft

-

Remote control

-

Interactive dashboards in real-time

-

Preventing future problems

FAQs

Most Commonly Asked Questions Regarding Aqualink's Smart Generator Monitoring Solution

Yes, our system includes a remote control feature that lets you start or stop your generators from any location with an internet connection. Indeed, you may use our technology to automatically plan certain ON and OFF periods.

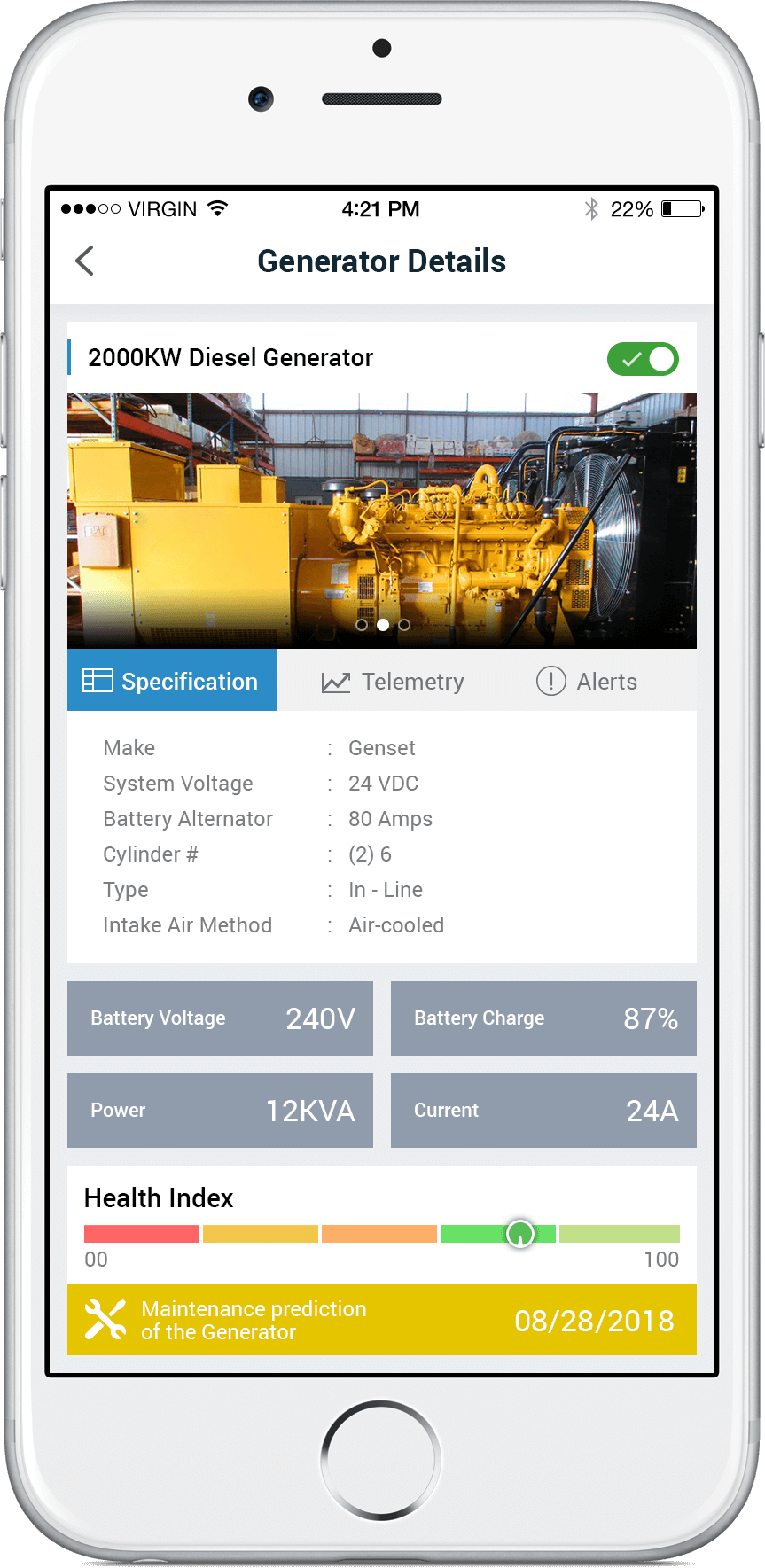

You may track fuel levels, fuel consumption, coolant levels, engine temperature and RPMs, anomalous noise levels, power output, capacity utilization, and operating hours with our system, and you can spot abnormalities.

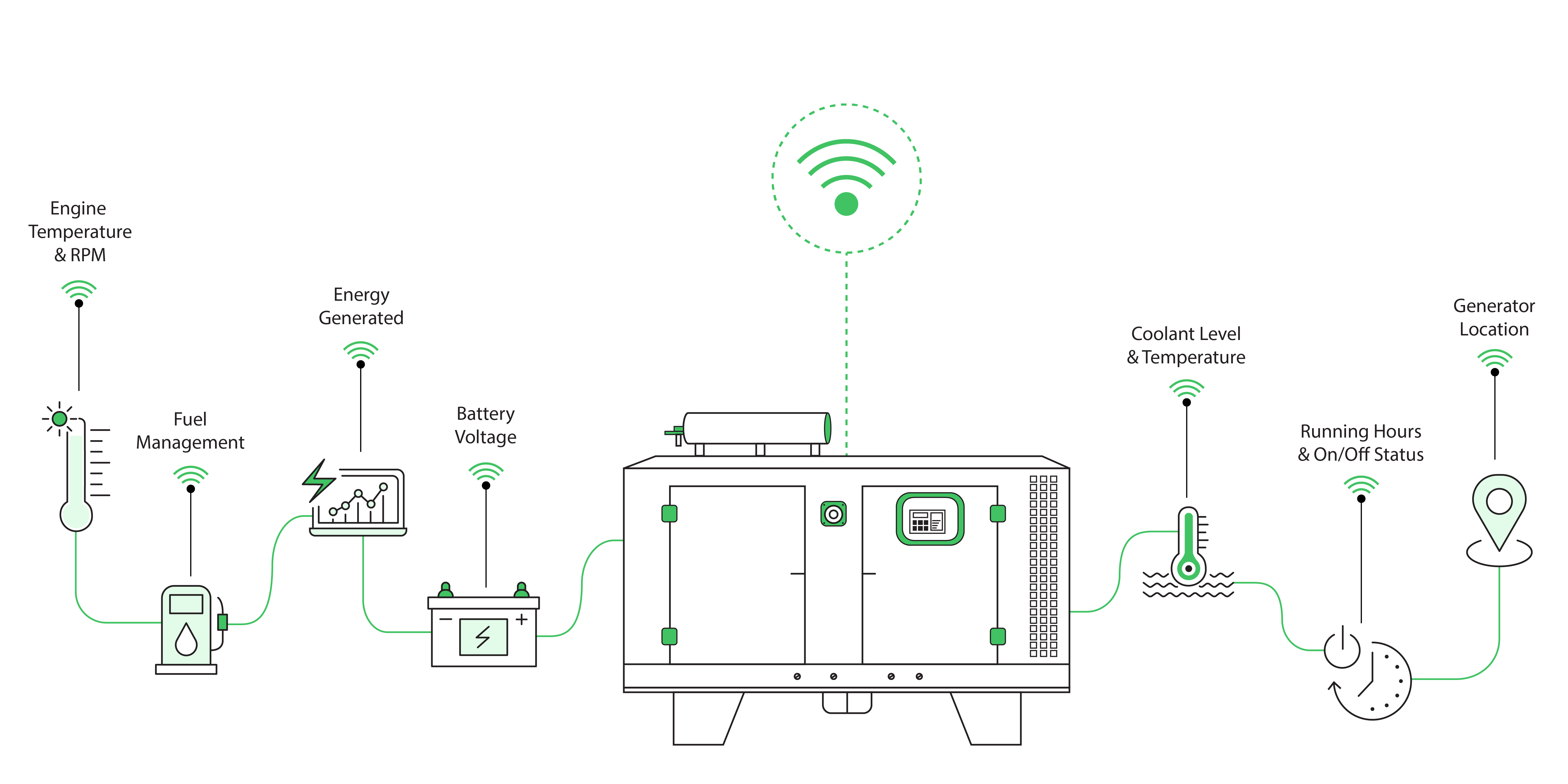

We put sensors on your generators to gather important data and transmit it over a gateway to our IoT platform. Our highly skilled machine learning algorithms then evaluate your data, and the resulting knowledge is subsequently sent to your mobile devices. The data may be used for predictive maintenance, automated scheduling, and generator health check monitoring.

The system will send you an email or text message, alert a monitoring station, and/or activate station alarms if a defect is found.